Beyond BIM: How Digital Twins Are Transforming Smart Construction and Facility Management

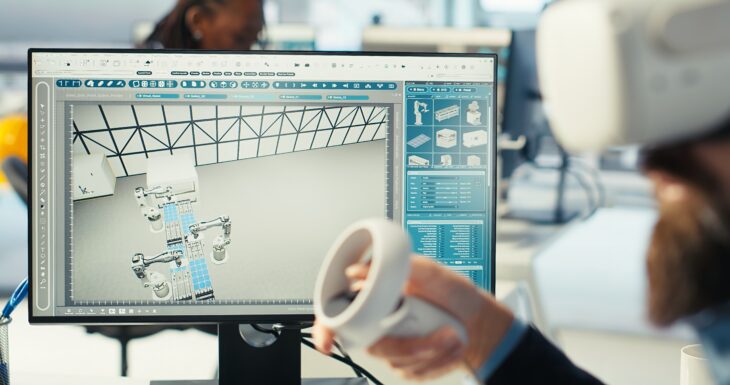

From BIM to Digital Twins: How Smart Infrastructure Is Being Built and Managed Today The architecture, engineering, and construction (AEC) industry is undergoing a major digital shift. While Building Information Modeling (BIM) has already transformed how projects are designed and coordinated, organizations are now moving a step further with Digital Twin technology. Together, BIM and Digital Twins are reshaping how buildings and infrastructure are planned, delivered, and managed throughout their entire lifecycle. This evolution is not about replacing BIM, but extending its value beyond construction into real-time operations, performance monitoring, and long-term asset optimization. From BIM Models to Living Digital Assets BIM provides a detailed, data-rich 3D model that helps teams visualize designs, detect clashes, and coordinate stakeholders before construction begins. However, traditional BIM models often remain static once a project is handed over. Digital Twins change this paradigm. A Digital Twin is a dynamic digital representation of a physical asset that continuously updates using real-time data from sensors, systems, and operational inputs. When BIM data is connected to cloud platforms and live operational information, it becomes a powerful decision-making tool that supports the entire asset lifecycle. Why Digital Twins Matter Beyond Construction The value of Digital Twins extends far beyond the construction phase. Organizations adopting this approach gain visibility and control across multiple stages: Design optimization using real-world performance insights Construction accuracy through data-driven coordination Operational efficiency with live monitoring of systems Predictive maintenance to reduce downtime and costs Sustainability tracking for energy and resource optimization Instead of relying on assumptions, stakeholders can make decisions based on real-time building behavior. Key Use Cases Across the Asset Lifecycle 1. Smart Building Operations Facility managers can monitor HVAC systems, lighting, occupancy, and energy consumption through a Digital Twin, enabling faster issue resolution and improved user comfort. 2. Predictive Maintenance By analyzing performance data, organizations can identify potential equipment failures before they occur—reducing unplanned downtime and extending asset life. 3. Infrastructure Performance Monitoring Digital Twins help track structural health, usage patterns, and environmental impact across complex infrastructure projects such as airports, campuses, and industrial facilities. 4. Data-Driven Sustainability With rising ESG goals, Digital Twins provide measurable insights into energy efficiency, carbon footprint, and operational sustainability. How BIM and Digital Twins Work Together BIM acts as the foundation for Digital Twins. Accurate models, structured data, and standardized workflows are essential to building an effective Digital Twin environment. Cloud-based platforms enable: Centralized data access Collaboration across teams Integration with IoT and operational systems Continuous updates throughout the asset lifecycle This seamless connection ensures that design intent is preserved while adapting to real-world conditions. Implementing BIM and Digital Twin Workflows in Practice Adopting BIM and Digital Twin solutions is not just a technology upgrade—it requires the right expertise, planning, and integration strategy. Organizations often face challenges such as data standardization, system integration, and change management during implementation. In India, organizations adopting Autodesk BIM and digital twin workflows often rely on experienced technology partners such as Sniper Systems & Solutions, who support enterprises with Autodesk software licensing, implementation guidance, and IT infrastructure alignment. Having access to the right technical knowledge and infrastructure support ensures that Digital Twin initiatives deliver measurable business value rather than remaining conceptual. Autodesk’s Role in Digital Twin Adoption Autodesk plays a key role in enabling BIM-driven Digital Twin workflows through its cloud-based ecosystem. Solutions such as Autodesk Construction Cloud and Autodesk Tandem help organizations connect BIM data with operational insights, enabling smarter asset management. These platforms allow teams to: Maintain a common data environment Transition smoothly from construction to operations Deliver structured digital handover data Support long-term facility performance monitoring This approach aligns closely with modern smart city and infrastructure initiatives. Benefits for Enterprise and B2B Organizations For enterprises managing large portfolios of buildings or infrastructure, BIM and Digital Twins deliver tangible advantages: Reduced operational costs Improved asset reliability Better compliance and reporting Enhanced collaboration across stakeholders Long-term ROI through lifecycle optimization Rather than treating buildings as static assets, organizations can manage them as intelligent, evolving systems. The Future of Smart Infrastructure As digital transformation accelerates, BIM and Digital Twins are becoming essential tools for organizations focused on efficiency, sustainability, and resilience. The shift toward data-driven asset management is no longer optional—it is a competitive necessity. Organizations that invest in these technologies today are better positioned to handle growing complexity, regulatory demands, and operational challenges in the years ahead. Final Thoughts BIM laid the groundwork for digital construction, but Digital Twins are unlocking its full potential. By connecting design data with real-time operational insights, organizations gain unprecedented visibility and control over their built environments. For enterprises seeking smarter ways to design, build, and operate assets, the integration of BIM and Digital Twin technologies represents a decisive step toward the future of intelligent infrastructure.

Read More